|

| |

Numerical Modelling (1997-2001)

|

Head Related Transfer Functions (HRTFs)

A

large body of research has been carried out on HRTF measurement (see Hebrank

and Wright, 1974, Mehrgardt and Mellert, 1977, Butler and Belendiuk, 1977,

Shaw and Teranishi, 1968, Shaw, 1974, Shaw, 1975, Shaw and Vaillancourt,

1985, Gardner and Martin, 1994, 1995, Møller et al, 1995, Hammershøi

and Møller, 1996, Carlile and Pralong, 1994, Pralong and Carlile,

1994 and Blauert, 1997).

The external ear transfer functions

are measured in the above publications at various places along the ear

canal, which gives rise to different responses. However, since up to 12-14

kHz only the longitudinal mode is present in the ear canal, the variation

of the position of the microphone does not distort the directionally dependent

HRTFs. |

|

| Mesh decimation and manipulation

The initial assumption made during

this work was that the highest resolution possible is required for the

mesh models of the head and pinnae. It was not clear at that stage what

accuracy is required and how sensitive will be the modelling of the acoustical

response to geometry approximations. There are currently a few techniques

available to obtain a computer model by scanning a physical model. These

include: Computed Tomography (CT), Magnetic Resonance Imaging (MRI), 3-D

ultrasonic imaging, etc. These are generally used for internal scanning

for medical purposes. The main advantage of the 3-D laser scanner technique

used in this research is that it can produce fairly quickly an accurate

mesh of the surface made out of triangles

In the initial work, the Cyberware

'Head and Face' colour 3-D scanner had been used. This scanner includes

the 3030/RGB digitising head and the PS motion system. It is mainly used

for medical applications, anthropometry, human interface, and in the film

industry. The geometry is captured by means of an optical range-finding

system that produces around a half of a million interconnected triangles

and their vertices in approximately 15 seconds. We refer to this scanner

as having a 'low-resolution'.

To begin with, it was found in

the scanning stage, that the accuracy of the pinna, which is our most important

part of the head, was poor, since during the motion of the scanner the

laser beam detects only unhidden parts. In the initial trials using the

KEMAR head, the rear part of the pinnae were significantly distorted, and

more importantly, the resulting concha was much shallower then the original

rubber ear of KEMAR, and without the details of the cavum and cymba concha,

helix, antihelix and fossa of helix. However, only after a set of simulations,

it was found that another scanning technique was required for high accuracy

modelling of the pinna.

Although still based on the technology

of laser scanning, the Cyberware 'Mini model' 3-D scanner is based on the

high-resolution 3030RGB/HIREZ scan head with a mid-size high-resolution

motion system. It moves slowly from side to side in the horizontal plane

in a straight line, parallel to the object. The principle of operation

is similar to the 'head and face' scanner, but with software controlled,

the data is accumulated through repeated scans at different angles of the

pinna. In this way, almost every curvature can be captured correctly. Even

the ear canal geometry can be obtained, by providing an additional model

with the original's cross-section. Then, the software matches the 'internal'

data with its own 'external' data by matching overlapping sections. The

duration of this scanning procedure is much longer, of the order of a few

hours; before any post-processing is applied to fix connectivity, rough

surface, holes, etc.

A few tools were developed and

used to integrate the two scans into a single mesh model for both KEMAR

head and YK head. Two types of decimated KEMAR models are presented below.

In both cases the original data included more than 400000 triangles (around

200000 vertices). The target was to obtain a suitable BEM mesh that could

be used to modelling at the maximum frequency possible with the IBEM in-core

solver . The mesh on the right was decimated using our proposed algorithm

that produces homogeneously distributed vertices, thus optimising its size,

geometry, and maximum frequency. This resulted in approximately 23000 elements

that can be used up to 15 kHz if four elements per wavelength are assumed

(for the ipsilateral ear), and 10 kHz if six elements per wavelength are

assumed (for the contralateral ear).

When a conventional mesh decimation

algorithm was used (the mesh in the middle, optimised for computer graphics

applications), and the number of elements was limited to 23000 elements,

a mesh with non-uniform distribution of vertices was obtained, where planar

areas were described with less triangles, and complex areas retained a

higher density of triangles to preserve the geometry. Note that with both

decimation algorithms the rendered image (on the left) is very similar.

This mesh in the middle could be investigated using the BEM reliably only

up to 1 kHz (!). This emphasises the significance of optimising the mesh

distribution while retaining the accuracy of complex shapes such as the

pinna. |

|

BEM simulation and measurement comparison

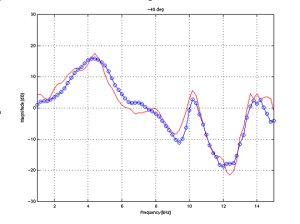

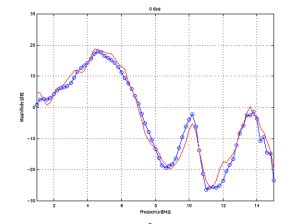

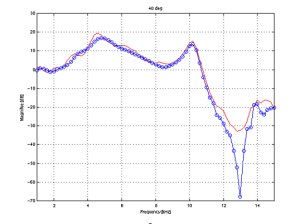

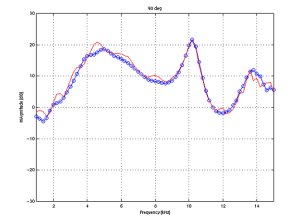

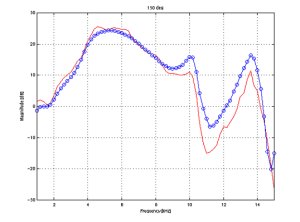

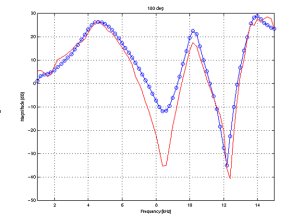

The following figures demonstrate

the accuracy of the simulation results when compared to measurements at

various angles in the horizontal plane.

The same simulated and measured

responses are shown at discrete angles. These show that errors of <1

dB appear up to 15 kHz. At other angles where sharper notches are found

errors increase locally at the position of the notch. It should be noted

that median plane simulation and measurement do not impose great difficulty

from the SNR point of view, since there are no effects of the shadowing

due to the head, which have strong attenuation at high frequencies. |

|

-40 deg.

|

0 deg.

|

|

40 deg.

|

90 deg.

|

|

130 deg.

|

180 deg.

|

Up |